The Xentara Platform

What exactly is Xentara?

“Xentara is a real-time capable universal industrial communications, control and convergence platform created to accelerate the Fourth Industrial Revolution and bring about the paradigms of Industry 4.0.”

Well, that’s quite a mouthful. So, as we prefer to say:

Xentara is: Enabling the Future

Table of Contents

What makes Xentara different?

There are lots of IoT implementations around. On this fragmented market, every provider presents their own isolated solution. But no system is an island. That’s why Xentara was created to bridge the gaps between different protocols, field buses, and control languages. But that is not all! Read on for details.

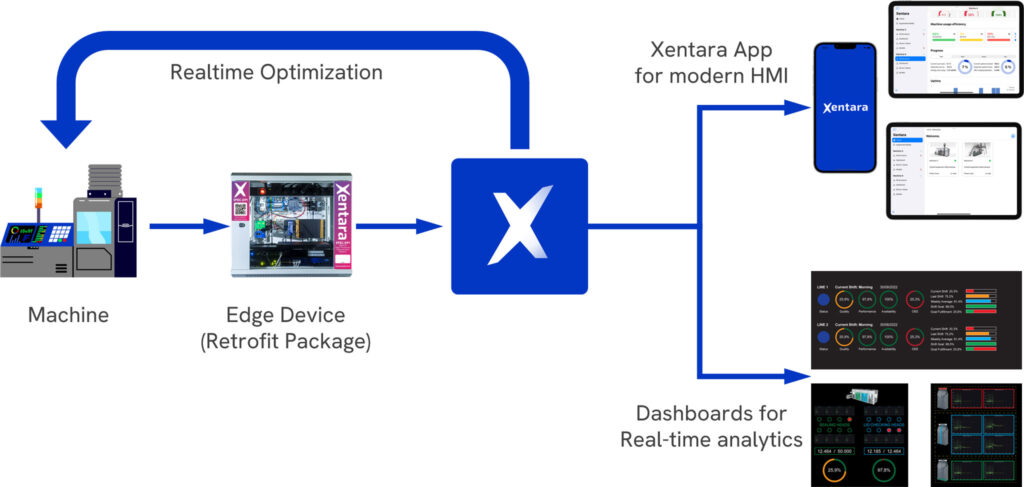

Xentara Closes the Control Loop!

Most IoT offerings are either data aggregators or cloud services (or a combination of both). In both cases, the problem is obvious: Analysis takes place “offline” and the results are only available after the fact. Any optimizations based on the analytics have to be painstakingly programmed into the system by a human operator and only show their effect on the next production run or system restart.

With Xentara’s unique realtime core, analyses can be performed right on the Industrial Edge and optimizations are directly written back into the machine controls – optimizing processes on the fly. By adding Machine Learning models, machine and devices can learn to optimize themselves during runtime. With Xentara, not only can new machines be made IoT-ready out of the box, but the ease of deploying and connecting the platform allows retrofitting legacy machines of all kinds. Thus, even Brownfield installations can be upgraded to be ready for data-driven industry!

(click images to enlarge)

The Xentara Advantage

Cost Efficient

- One single open platform

- Freedom from proprietary control solutions

- Grows with the entire product lifecycle

- Keep knowledge inhouse and overall cost down

- Pay per use with a maximum of customization

Time Saving

- Concentrate on creating innovations and new business models

- Outsource what is not part of your value chain

- Enable and empower your PLC developers, operators, data scientists, UI/UX designers, system architects and tech specialists

Cutting Edge

- Unique timing model for real-time control of monolithic and distributed systems

- Goes beyond the accuracy and cycle speed of existing PLCs

- Multi mesh security

- Semantic and object-oriented data abstraction

Scalable and Modular

- Technology independent and highly flexible platform

- Applicable with any kind of interface of the whole IT office- and OT shopfloor

Future Proof

- From retrofit to greenfield solution and beyond

- Low entry barrier even with emerging technologies and future requirements that are currently unknown

Guiding Principles

The Xentara platform is based on four primary core principles defining its main functionalities:

CONNECT

- Any Data Source

- Any Data Consumer

- Any Protocol

Employing a modular Skill framework, the Xentara platform can integrate any kind of industrial field bus or communication protocol as well as IT and cloud services or enterprise applications.

If it produces data, Xentara can read it. If it needs data, Xentara can feed it. If it processes data, Xentara can work with it.

COMMUNICATE

- Data Structure

- Homogenization

- Semantic Model

Having connected your south- and northbound systems, Xentara handles all internal and external communications. No matter where your data is kept, you can access it from anywhere, whether local or remote.

Data is stored in a semantic structure, making it easy to navigate and human readable. The shared data model spans system boundaries.

CONTROL

- Real-Time

- Deterministic

- IT/OT Convergence

Current IT solutions don’t fulfil the strict timing requirements for live interaction with industrial machinery while OT lacks flexibility, computing power and connectivity.

Xentara’s real-time communication core seamlessly bridges IT based analytics and logics with deterministic machine controls.

COGNIFY

- Data Visualization

- Analytics

- (Edge) AI / ML

Bringing intelligence right to the industrial edge, Xentara enables you to deploy AI and ML instances on the shop floor. Besides freeing you from cloud provider dependencies, this allows real-time analytics and optimization.

Data and analysis results can be visualized in different ways, including the Xentara app.

These four key components are what makes Xentara the perfect bridge between the different worlds of Operational Technology and Information Technology. The platform allows for fast and simple Industrial IoT implementations. It is applicable both to new designs as well as retrofits and Brownfield overhauls.

Key Features - The Xentara Core

Expandability

- Expand Xentara in limitless ways through a modular Skill system

- Incorporate new protocols or field buses easily

- Connect to ERP, MES, CAQ, or other Business Intelligence solutions

- Adapts to all of your current and future needs

Precision Timing

- Realtime is not just about speed but precision and synchronicity

- Xentara synchronizes timings across distributed systems

- Configurable multi-pipeline Timing Model ensures that all processes stay in step even in multicore and multiprocessing environments

Safety and Security

- Compatible with cutting edge encryption standards

- Package Integrity Control and Information Retention Systems ensure safe and stable communication

- Fine grained user roles for access rights management

- Multi-Mesh Security across all applications

Brownfield Support

- Legacy equipment can be made IoT-ready with minimum effort

- Machine fleets in active production can be integrated and optimized without expensive replacement procedures

- Upgrades require minimal downtime

Performance

- Unprecedented access times and transfer speeds

- Receive all of your data instantly

- Say goodbye to waiting for reports for hours or days

- Harness the value of your data right at the moment that it is generated

Unified Architecture

- Semantic model with unified namespace for local and remote data points

- Unified shop floor architecture enables swift configuration

- Full Unicode support for multi- language models and interfaces

- Application developers can access any subsystem through a unified interface

Additional Functionality - Xentara Skills and Extensions

A vast range of Skills for all kinds of different purposes is already available and growing continuously. This is just an excerpt of the most important ones that our industrial customers are currently using:

Southbound Connector

- EtherCAT Driver

- Modbus Driver

- OPC UA Client

- National Instruments Rack Driver

Northbound Connector

- MQTT Client

- Web Service

- OPC UA Server

- Modbus Server

- Sparkplug Edge Node

PLC Connector

- Beckhoff ADS Driver

- S7 Driver

- ARTI Driver

- CODESYS Driver

Edge AI

- ONNX Engine

- Torch Engine

- Tensorflow Lite Engine

Hardware Driver

- Comedi Driver

- Pickering PXI Driver

- SPI Driver

Cloud Database Connector

- Clarify Client

- InfluxDB Client

Test System Integration

- Cobra Client

Automation

- FMU Driver

Most Skills serve multiple purposes.

The ONNX engine, e.g., allows you to access almost any Machine Learning interface currently in widespread use. Lots of simulation systems and control logics speak FMU.

New Skills are constantly being developed and released. Please inquire directly for any protocol or interface not listed – chances are it’s already in development or on our roadmap.

Xentara is connecting worlds...

What is Included in a Xentara License?

Xentara Core

- Industrial Convergence, Communication & Control Platform

- Semantic Model

- Timing Model

- Process Control

- Data Preprocessing

- Integrated Debugger

Workbench

- Universal Configuration Tool

- Graphical User Interface

- Supports wide range of Xentara Extensions

- Constantly updated as new extensions become available

- No programming required

Extensions

- Automation Skills

- Protocol connectors (south- and northbound)

- PLC connectors, Soft-PLC, machine control

- Cloud connectors

- (Co-) Simulation interface

- Edge AI

- Microservices

- Websocket

- etc.

The Xentara Core and Workbench are included with every license. Available Extensions are determined by license type.

Your Data Wherever You Want - The Xentara App

One of the biggest problems in industrial digitalization is that the more data becomes available, the harder it becomes to make sense of it. Rising levels of complexity require not only more storage space and computing power, but primarily good data handling strategies. Otherwise, it is easy to be overwhelmed by the sheer flow of information. To realize the value within that data, you need the right tools.

That is why we developed an easy to use tablet and smartphone app as a seamless interface.

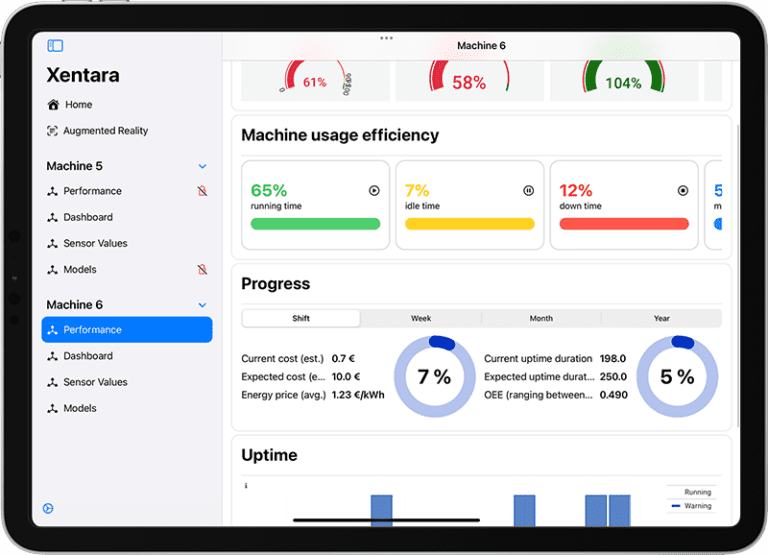

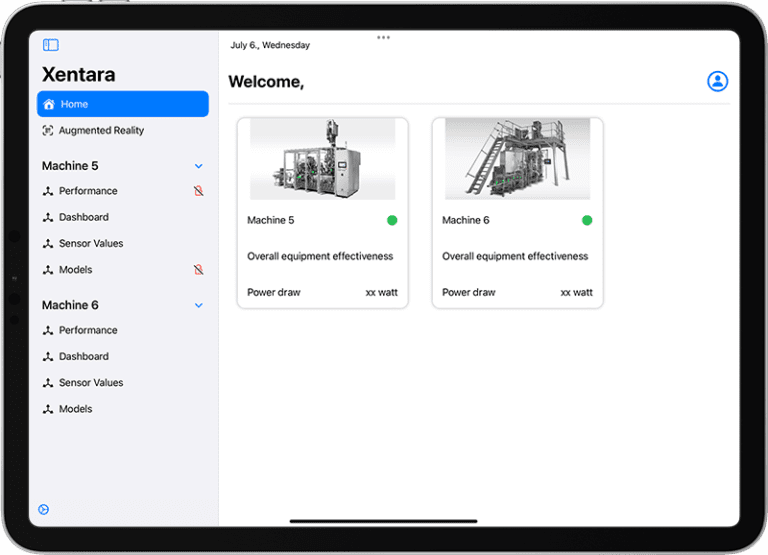

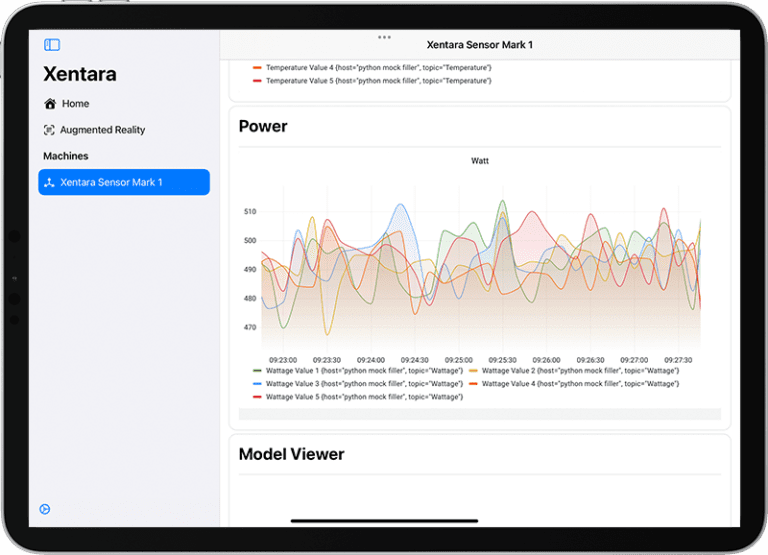

Visualization

The app displays your data in a wide variety of graphical representations.

Scalable timelines allow exploring historical data over user selected spans ranging from months to milliseconds.

Analytic results and trends can be mixed with live machine data for direct comparison.

AI-generated summaries help the user gain an overview over huge datasets at a glance.

Augmented Reality

The App uses a powerful AR framework to help you navigate machines and associated data.

Scan anchor points on machines to see sensor data overlaid on the live picture captured by your camera.

Put virtual models of machines anywhere in the room and explore the finest details. The model always displays the current live state of the actual machine.

For remote maintenance, you can see any faults immediately.

Real-Time Control

Information flows both ways. Thanks to Xentara’s real-time capability, machines can be remote controlled right from your mobile device.

Either the complete Human-Machine-Interface or just the desired functions can be reproduced in the Xentara App and operated via touchscreen. Change effects are seen immediately in the live display.

One app can control an unlimited number of machines.

The Xentara App is currently available for iPad, iPhone and Mac via Testflight. Please contact us for early access.

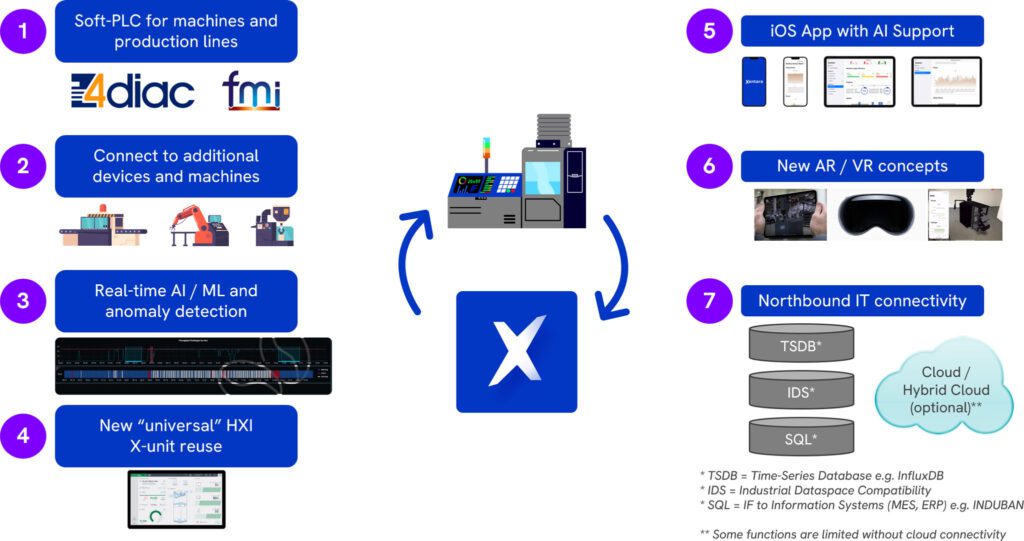

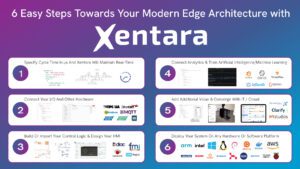

Six Easy Steps Towards Your Modern Edge Architecture

Creating Industry 4.0 compliant architectures can be a daunting task. Utilizing the power of Xentara, building a smart architecture is possible right on the Industrial Edge.

This allows you to leverage artificial intelligence or machine learning as well as all kinds of machine metrics and software based control logics to digitalize whole production sites without the need for new machines or expensive cloud services.

Our engineers have broken down the process into six easy steps.

System Requirements

- Processor

- x86-64

- ARM processor capable of running Linux / Windows

- MMU controller required

- 64bit (Windows/Linux): ARMv8-A instruction set required

- 32bit (Linux only): ARMv7-A with VFPv3-D16 floating point support required

- Storage

- 200MB free disk space

- Operating system

- Windows 10 64 bit

- Linux

- Reference distributions: Debian 11, Ubuntu 20.04.2.0 LTS or similar

- Please inquire for support of other Linux distributions

- Deployment

- Windows: MSI installer

- Linux: apt install from online repository

- Xentara can be deployed in virtualized environments (Docker containers et al.) with certain limitations (e.g. with regard to real-time behavior or system timing control)

- Deterministic real-time data processing and communication requires real-time capable operating system (i.e. Preempt-Patch for Linux)

- Distributed process timing control requires TSN capable Ethernet adapter and routers / switches